Demand Controller for Peak Demand Reduction

The DemandMiser helps reduce demand peaks by temporarily cycling or reducing electrical loads during high-demand periods. This lowers the “Maximum Demand Charge,” which is based on the highest recorded peak each month when multiple loads run simultaneously.

Installation History

Theory & Application

Why is the DemandMiser Unique?

The DemandMiser uses an AI sophisticated load shedding algorithm that provides automatic load limit adjustment. The system has programmable outputs for cycling loads on a priority basis.

This ensures that the equipment being shed is not continually shed at the same time, so daily operation is not affected. In addition, the DemandMiser automatically resets itself so it is synchronized with the utility meter for bill verification purposes.

How Does it Work?

DemandMiser can receive the kW/KVA values from 2 different kinds of inputs:

- Pulse Input (utility meter)

- Analog/Digital Input with meter or CTs

The DemandMiser then sheds loads via a dry contact interface.

What Loads are Shed?

The DemandMiser is installed in the electrical room and is connected to sheddable loads like:

- Activate Generator for Load Shedding

- HVAC

- Medium Temperature Compressors

- Low Temperature Compressors

- Electric Heaters

- LED Lighting (Reduce by 50%)

Demand Control Overview

The DemandMiser is the only demand management system that offers an AI-driven load shedding algorithm and web interface to ensure maxium energy saving without interfering with facility operation.

Specifications

| Type | Description |

|---|---|

| Platform | Embedded System |

| Communication | Ethernet, Modbus, Web Browser |

| Input Type | Analog Input or Pulse Input |

| Dry Contact Interface | |

| # of Loads: 8 (outputs) | |

| Modes of Operation | Automate Demand Control |

| User Interface Capabilities | Change Demand Settings |

| View Demand Settings | |

| View Overall Energy Usage | |

| Dimensions | H-20” X W-20” X D-8” |

| Enclosure | Material Steel – NEMA 12 |

Features

- Controls Demand Peaks

- Controls Electric Generators

- Automatic Load Limit Adjustment

- Interfaces with EMS and 3rd Party Systems

- A.I. Load Shedding Algorithm

- Monitor Energy Usage on Electrical Loads

Industrial Applications

From mineral processing plants to car manufacturing plants the Maximum Demand Controller is the solution for kW reduction with load shedding.

Each maximum demand controller is built with industrial grade components to provide reliability for all environments and the system is capable to communicate via backnet protocol in addition to the standard ethernet. Example of sheddable loads:

-

Off-peak Generator Support

-

Pumps

-

Furnaces

-

Machinery

-

Generators

-

Lights

-

Compressors

Commerical Applications

The maximum demand controller easily integrates with existing building management & refrigeration systems (Emerson, Danfoss, Johnson Controls) to control peak demand.

With a dry contact interface the existing building system can be programmed to shed the specific load when it gets a signal from the DemandMiser. Example of sheddable loads.

-

Off-peak Generator Support

-

Lighting

-

Heating

-

Compressors

-

Air Conditioning

-

Lights

FAQ

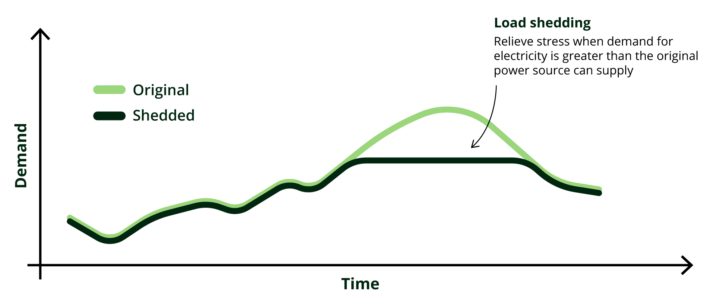

Demand usage is the total amount of electricity being used by a consumer during a defined time period. Demand varies from hour to hour, day to day and season to season. This usage that is expressed in kilowatts (not kilowatt-hours) and is called the demand peak on the system. The utility records demand over a 15-minute time period. The company is charged for the highest 15-minute usage recorded on the demand meter. After the utility reads the meter each month, demand is reset to zero and the meter starts over, recording the highest 15-minute usage for the next billing period. You will see this charge on your power bill.

- kva charge

- kWh charge (not kW)

- demand charge

- demand usage

The demand charges many times exceed 50% of their total electric bill. This makes “Load Shedding” very attractive to reduce companies operating costs.

In order to reduce demand peaks in a facility, the Maximum Demand Controller monitors the main utility meter in the facility and by measuring every 5 minutes the demand usage, the DemandMiser will perform automatic load shedding when it notices a demand peak is coming. Shown below are example loads that would be connected for demand control:

- Compressors

- Fan Motors (with variable speed systems)

- Electric Heaters

- Pumps

- Air Conditioners & Others

You can still read your existing content as usual, but you won’t be able to add new content. However, you can delete existing blocks to free up space.